- Unternehmensübersicht Das Herz von Shanghai Metal Vision und Philosophie Partnerschaft Zertifizierungen Unternehmenskultur

- Unser Service Projekt-Design Wartung und Service Herstellung Transformation und Aufrüstung Lagerung und Logistik Verarbeitung und Handel

- Management Unsere Geschichte Globale Verantwortung

- Beschaffungszentrum Praktikum

- Metall Aluminiumprodukte Kupferprodukte Metallisch beschichtete Produkte Edelstahlprodukte Stahlprodukte Sonderlegierung

- Konstruktion Stahlgitter Lagerregal Stahlstruktur Stahlbrücke Gerüstbau Baumaterial Chemische Rohstoffe One Stop Solutions for Projects

- Containers ISO Standard Container Gerätecontainer Lagerbehälter Container Haus Reefer / Isolierbehälter Offshore Container

- Maschinen Formmaschine Andere Maschinen Schneidemaschine Verarbeitungsmaschine Biegemaschine Ziegelmaschine Motor

- Mechanische Produkte Fahrzeugindustrie Verschiedenes Festmacher Schiffsausrüstung Druckbehälter

- Elektrisches System Elektrisches Kabel Automatisierung Machtverteilung Solarenergie System Elektrisches Schutzsystem Transformator Fließband Blitzsystem

- Medizinisches Zubehör Fütterungsprodukte Atemwegsprodukte Pflegeprodukte Injektionsprodukte

- Baumaschinen

- EPC-Projekt

- Erdölleitung

- Wasserleitung

- Gas Leitung

- Boots- und Liegezubehör

- Metall zur Dekoration

- Transformator-Komponenten

- Wärmetauscherrohr

- Klimaanlage Ersatzteile und Zubehör

- Kessel

- Küchen- und Badezimmergerät

- Metall für Haushaltsgeräte

- Solarstromgerät

- Aufzug

- Dach und Decke

- Kabel

- Tank

- Verpackung

- Maschinen und Anlagen Ersatzteile und Zubehör

- Formenwerkzeug

- Autoteile

- Gleis- und Kranbahn

- Hardware-Anpassung

- Schleifmittel

- Straßenbaumaschinen

- Elektronische Bauteile

- Bau- und Ausbaumaterialien

- Türen und Fenster

- Kühlschränke

- Pressemitteilung Nachrichten aus der Metallindustrie Nachrichten von Maschinen und Anlagen Nachrichten von Bau und Gebäude Nachrichten von mechanischen Produkten Nachrichten von Containern Nachrichten von Elektrik System Nachrichten von medizinischem Zubehör

- Medienbibliothek Videos Bilder Folgen Sie den sozialen Medien in Shanghai

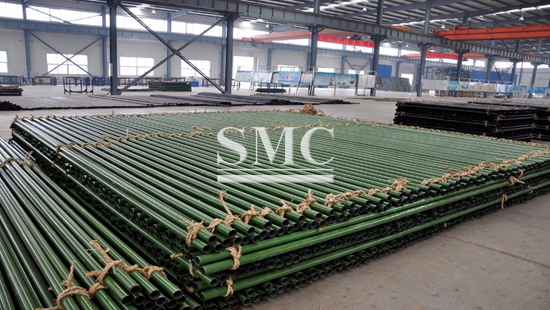

Enameled Coating Tubes

Thickness: 0.5mm - 15mm

Outside Diameter: 8mm-325mm

Length: Customized

Capacity: 1000 Mt/month

Material: 10#, 20#, 16Mn, A106(B,C), Q235, Q345 etc

1. The enamel tube has the characteristics of high temperature resistance, corrosion resistance, smoke resistance, and the service life is 3-5 times that of the ordinary air preheater.

2. The enamel steel tube is manufactured with the enamel which is our own developed with scientific formula and is evenly coated on the surface of the steel tube by the auto enamel tube production line.

3. To use enamel tube as the heat exchanger parts will be anti-abrasion and anti-corrosion, the surface is smooth and low cost of maintenance.

4. To adapt the different boiler burning type, different fuel and different fume ingredient, we developed the different enamel tube air preheaters to fit different medium.

Raw Steel Coil - Slitting Into Request Width - High Frequency Straight Seam Welding (Hot Extrusion Process For Seamless) - Clearing burrs -

Cutting Request Length -Enameled Coating Process - Packing

Enameled Coating Tubes

1. thickness: 0.5mm - 15mm

2. Outside Diameter: 8mm-325mm

3. Length: Customized

4. Capacity: 1000 Mt/month

5. Material: 10#, 20#, 16Mn, A106(B,C), Q235, Q345 etc

Packing:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

Applications:

Air Pre-Heater, Economizer, Water-Cooled Wall

HIER

FÜR

PREIS

We will contact with you within 8 hours