- Unternehmensübersicht Das Herz von Shanghai Metal Vision und Philosophie Partnerschaft Zertifizierungen Unternehmenskultur

- Unser Service Projekt-Design Wartung und Service Herstellung Transformation und Aufrüstung Lagerung und Logistik Verarbeitung und Handel

- Management Unsere Geschichte Globale Verantwortung

- Beschaffungszentrum Praktikum

- Metall Aluminiumprodukte Kupferprodukte Metallisch beschichtete Produkte Edelstahlprodukte Stahlprodukte Sonderlegierung

- Konstruktion Stahlgitter Lagerregal Stahlstruktur Stahlbrücke Gerüstbau Baumaterial Chemische Rohstoffe One Stop Solutions for Projects

- Containers ISO Standard Container Gerätecontainer Lagerbehälter Container Haus Reefer / Isolierbehälter Offshore Container

- Maschinen Formmaschine Andere Maschinen Schneidemaschine Verarbeitungsmaschine Biegemaschine Ziegelmaschine Motor

- Mechanische Produkte Fahrzeugindustrie Verschiedenes Festmacher Schiffsausrüstung Druckbehälter

- Elektrisches System Elektrisches Kabel Automatisierung Machtverteilung Solarenergie System Elektrisches Schutzsystem Transformator Fließband Blitzsystem

- Medizinisches Zubehör Fütterungsprodukte Atemwegsprodukte Pflegeprodukte Injektionsprodukte

- Baumaschinen

- EPC-Projekt

- Erdölleitung

- Wasserleitung

- Gas Leitung

- Boots- und Liegezubehör

- Metall zur Dekoration

- Transformator-Komponenten

- Wärmetauscherrohr

- Klimaanlage Ersatzteile und Zubehör

- Kessel

- Küchen- und Badezimmergerät

- Metall für Haushaltsgeräte

- Solarstromgerät

- Aufzug

- Dach und Decke

- Kabel

- Tank

- Verpackung

- Maschinen und Anlagen Ersatzteile und Zubehör

- Formenwerkzeug

- Autoteile

- Gleis- und Kranbahn

- Hardware-Anpassung

- Schleifmittel

- Straßenbaumaschinen

- Elektronische Bauteile

- Bau- und Ausbaumaterialien

- Türen und Fenster

- Kühlschränke

- Pressemitteilung Nachrichten aus der Metallindustrie Nachrichten von Maschinen und Anlagen Nachrichten von Bau und Gebäude Nachrichten von mechanischen Produkten Nachrichten von Containern Nachrichten von Elektrik System Nachrichten von medizinischem Zubehör

- Medienbibliothek Videos Bilder Folgen Sie den sozialen Medien in Shanghai

MONEL K-500

STANDARD PRODUCT FORMS:

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

A precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of MONEL alloy 400 with greater strength and hardness. It also has low permeability and is nonmagnetic to temperatures as low as -150°F (-101°C). Used for pump shafts, oil-well tools and instruments, doctor blades and scrapers, springs, valve trim, fasteners and marine propeller shafts.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N05500 BS 3072 – 3076 (NA18) ASTM B 865 SAE AMS 4676 DIN 17743, 17752 –17754 Werkstoff Nr. 2.4375 QQ-N 286 NACE MR-0175/ISO 15156 ISO 6208, 9723 – 9725 ASME Code Case 1192

LIMITING CHEMICAL COMPOSITION, %

Nia.........63.0 min.

Cu..... 27.0 – 33.0

Al.......2.30 – 3.15

aPlus Co.

Ti.......0.35 – 0.85

Fe........... 2.0 max.

C...........0.25 max.

Mn.......... 1.5 max.

S...........0.01 max.

Si............ 0.5 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.305

g/cm3......................................................................... 8.44

Melting Point, °F......................................................2400 – 2460

°C......................................................1315 – 1350

Specific Heat, Btu/lb •°F.....................................................0.100

J/kg •°C........................................................... 419

Curie Temperature, °F........................................................... -150

°C.......................................................... -100

Permeability at 200 Oersted (15.9 kA/m).....................1.002

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.6

21 – 93°C, μm/m •°C............. 13.7

Thermal Conductivity, Btu • in/ft2• h•°F............................ 121

W/m•°C............................................17.5

Electrical Resistivity, ohm • circ mil/ft.............................. 370

μΩ•m...............................................0.615

Young's Modulus at RT, 103 ksi...............................................26

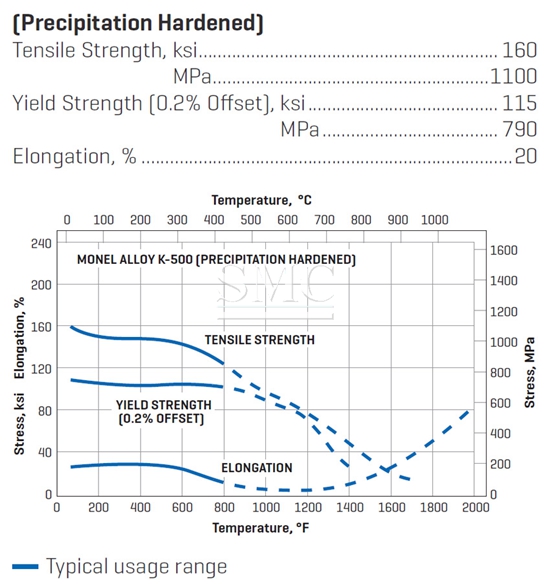

TYPICAL MECHANICAL PROPERTIES

Character

Resistant to seawater and steam at high temperatures.

Excellent resistance to rapidly flowing brackish water or seawater.

Excellent resistance to stress corrosion cracking in most freshwaters.

Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated.

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids.

Excellent resistance to neutral and alkaline salt.

Resistance to chloride induced stress corrosion cracking.

Good mechanical properties from sub-zero temperatures up to 1020° F.

High resistance to alkalis.

Application

Marine engineering.

Chemical and hydrocarbon processing equipment.

Gasoline and freshwater tanks.

Crude petroleum stills.

De-aerating heaters.

Boiler feed water heaters and other heat exchangers.

Valves, pumps, shafts, fittings, and fasteners.

Industrial heat exchangers.

Chlorinated solvents.

Crude oil distillation towers.

HIER

FÜR

PREIS

We will contact with you within 8 hours